Stress Concentration

The fracture of a material is dependent upon the forces that exist

between the atoms. Because of the forces that exist between the

atoms, there is a theoretical strength that is typically estimated

to be one-tenth of the elastic modulus of the material. However,

the experimentally measured fracture strengths of materials are

found to be 10 to 1000 times below this theoretical value. The

discrepancy is explained to exist because of the presence of small

flaws or cracks found either on the surface or within the material.

These flaws cause the stress surrounding the flaw to be amplified

where the magnification is dependent upon the orientation and

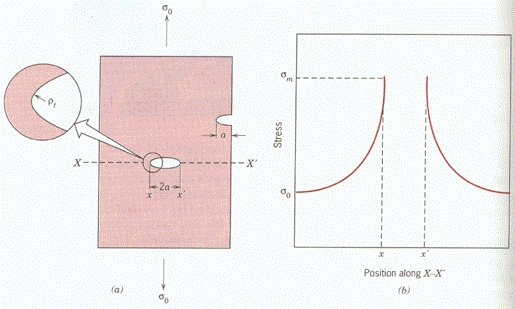

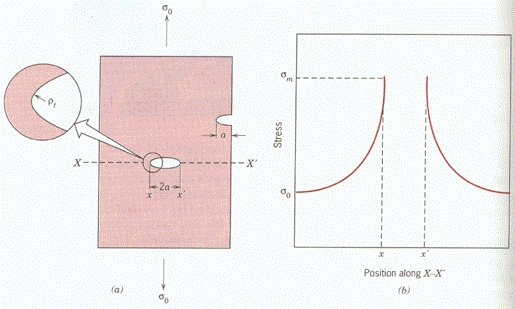

geometry of the flaw. Looking at fig. 1, one can see a stress

profile across a cross section containing an internal, elliptically-shaped

crack. One can see that the stress is at a maximum at the crack

tip and decreased to the nominal applied stress with increasing

distance away from the crack. The stress is concentrated around

the crack tip or flaw developing the concept of stress concentration.

Stress raisers are defined as the flaws having the ability

to amplify an applied stress in the locale.

Determination of the Maximum Stress at the Crack Tip

If the crack is assumed to have an elliptical shape and is oriented with its long axis perpendicular to the applied stress, the maximum stress, sm can be approximated at the crack tip by Equation 1.

The magnitude of the nominal applied tensile stress is so; the radius of the curvature of the crack tip is r; and a represents the length of a surface crack, or half the length of an internal crack.

Determination of Stress Concentration Factor

The ratio of the maximum stress and the nominal applied tensile stress is denoted as the stress concentration factor, Kt, where Kt can be calculated by Equation 2. The stress concentration factor is a simple measure of the degree to which an external stress is amplified at the tip of a small crack.

Stress Concentration Considerations

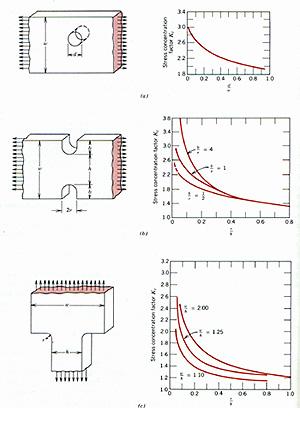

It is important to remember that stress amplification not only occurs on a microscopic level (e.g. small flaws or cracks,) but can also occur on the macroscopic level in the case of sharp corners, holes, fillets, and notches. Fig. 2 depicts the theoretical stress concentration factor curves for several simple and common material geometries.

Stress raisers are typically more destructive in brittle materials. Ductile materials have the ability to plastically deform in the region surrounding the stress raisers which in turn evenly distributes the stress load around the flaw. The maximum stress concentration factor results in a value less than that found for the theoretical value. Since brittle materials cannot plastically deform, the stress raisers will create the theoretical stress concentration situation.

Reference:

Submitted by Anita Noble

Virginia Tech Materials Science and Engineering

http://www.sv.vt.edu/classes/MSE2094_NoteBook/97ClassProj/anal/noble/stress_conc.html

Last updated: 5/4/97